Our product range

The E-series ground screws can be optionally equipped with an excentre set depending on the application. The excentre set allows you to make precise adjustments and ensures a perfect, vertical positioning of the object that you want to install. The system is particularly suitable for the resonance and vibration dampening installation of poles and masts for example.

The F-series ground screws are equipped with round or square flanges. The fixation of the bearing object made possible by this ensures the highest possible stability and safety, even with large or extreme structural loads.

The G-series ground screws are equipped with either one, three or four threaded screws. They are ideally suited for the quick, vertical and permanent installation of masts and fence posts, for example. Optionally, the fence posts, for example, can also be quickly and permanently fixed into place with the special granulate.

The M-series ground screws have a centred M-thread which allows the object that is to be carried to be directly screwed onto the ground screw. They are particularly suitable for constructing prefabricated garages and containers, for example.

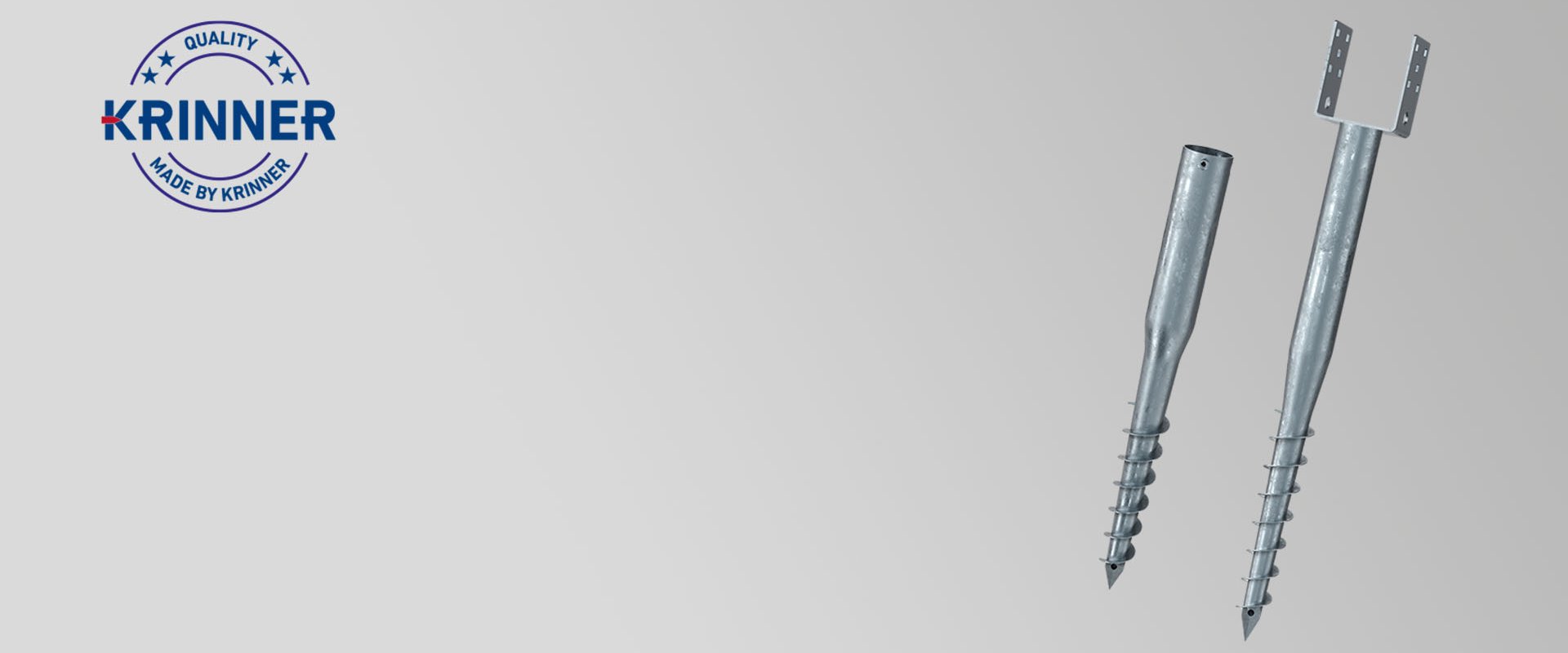

The U-series ground screws have been specially designed for all regularly-dimensioned timber beams. They are perfect for the simple and fast mounting of horizontal and vertical timber beams, for example during carport and wooden terrace construction.

Our V-series ground screws are extendable. The ground screws can be extended according to the project requirements and were specially developed for projects with high loads. The products V89, V114 and V140 come with DIBt-approval.

The X-series ground screws were developed for special applications. This product can be used to produce made-to-measure foundations. The screws are tailor-made individually according to construction requirements.

The advantages of Krinner ground screws

Eco-friendly

Our ground screws don’t harm the environment during installation or after use. No soil needs to be moved for the installation and the foundations can be removed without leaving behind any residue.

Efficient

The installation process is significantly faster than that of traditional foundation solutions. Individual foundations can be created in just a few minutes and house foundations take just a day to be put in place.

Safe

Based on the thousand-year-old pile foundation principle, ground screws offer a safe and secure foundation solution. They can carry the same load as some conventional concrete foundations.

The KRINNER blog

Which machines can be used to drive in ground screws?

Which machines can be used to drive in ground screws?

Entry-level manual ground screw drivers

The original aid for manual installation is the screw driving tool or rod. They can be used to drive ground screws into the soil by hand without electric or hydraulic help. However, these tools are recommended for the installation of very small ground screw foundations in garden and hobby construction projects, such as when building a small sunshade holder, for example.

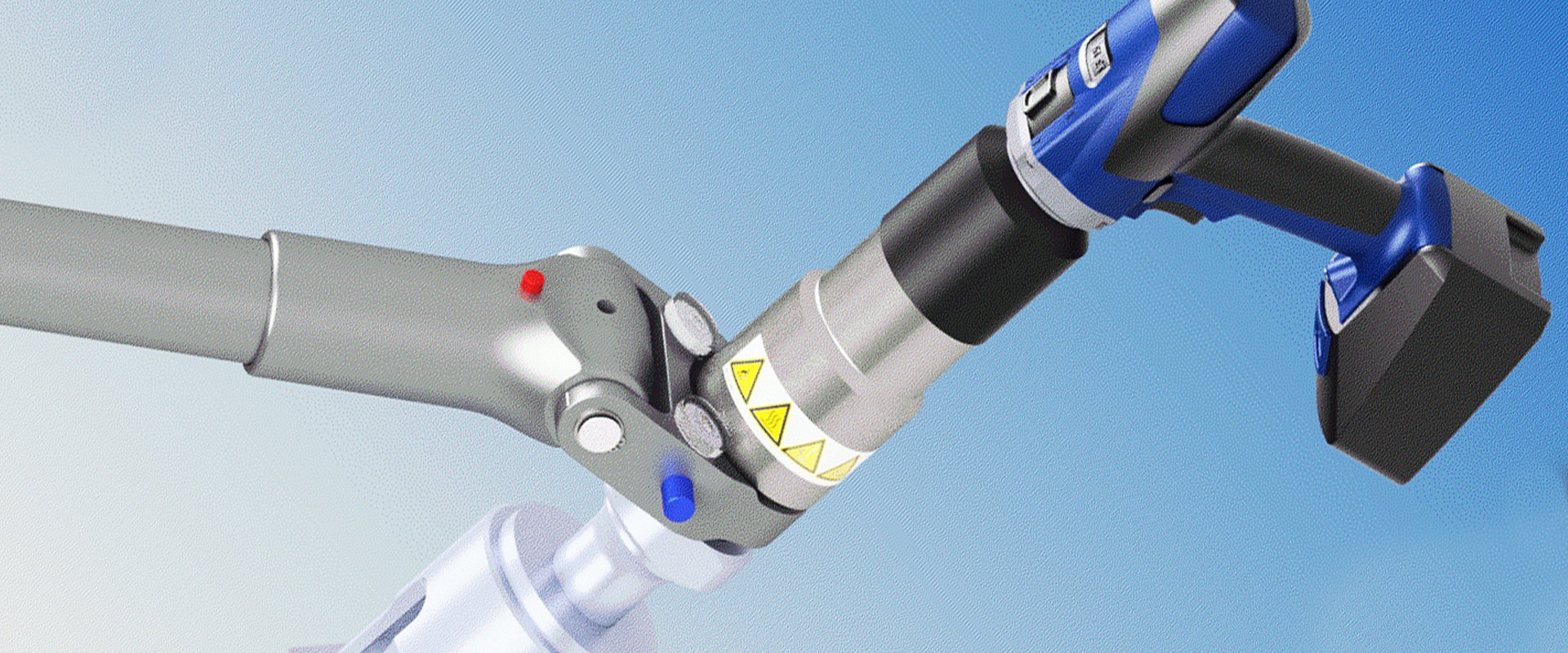

The electric manual ground screw driver should be thought of as an entry-level model for professional construction projects. It’s a comfortable option for installing ground screws at an affordable price. An electric manual ground screw driver consists of a drive unit, a handle and a telescopic rod for discharging the torque.

You can work effectively with this machine as it can be operated by one person and it makes it possible to easily install professional foundations, even on narrow and difficult to access construction sites. The device is relatively easy and light to transport and it even fits in the trunk of a car.

Manual ground screw drivers enable torques of up to 3,500 Nm and, depending on the soil composition, can be used to drive in ground screws with a diameter of up to 140 mm and a pipe length of 1600 mm. Despite the electrical drive, some manual force is still required. With the and the , KRINNER Schraubfundamente GmbH offers two different variations of this type of machine.

Challenging tasks and considerable scope for action

Challenging tasks and considerable scope for action

We are looking for dedicated and motivated people who will help us to drive forward our company in an exciting and innovative industry. We place great value on personal initiative, responsibility and personal development. You can expect a welcoming working environment that offers all the amenities of a modern employer. This includes flexible working hours, options for continuous further development and exciting career opportunities. Interested?