Six important things that you should bear in mind when installing screw foundations

Six important things that you should bear in mind when installing screw foundations

1. The subsoil check

Alongside the clarification about the subsoil with regards to its composition and load-bearing capacity, it’s also very important to check whether there are any kind of pipelines running under the construction site before the foundation installation begins. This means that you can avoid unintentionally damaging gas, electricity, water or telecommunication lines, which would not only be an expensive mistake but also a very dangerous one. Another important point: some construction sites are located on former munitions factories or in areas that were targeted by bomb attacks during the First and Second World Wars. It must absolutely be ensured that there are no unexploded bombs on the site as this can pose a risk to life.

2. Preliminary drilling makes the driving in easier

It’s recommended that you perform a preliminary drilling at each of the ground screw installation points to ensure high levels of precision and to make the installation more efficient. These should be significantly smaller in diameter than the foundation that you will be installing. The drilling can be done either partially or cover the whole length. It should be done either with the help of a probing spike or by hand with a traditional impact drill. (By probing spike, we mean a displacer in the shape of a thin, very robust screw.) As well as increasing the precision, the process also helps the installer to identify any hard layers or obstacles in the substrate. This means that any damage to the foundations or any “slipping” can be avoided. This process allows for a more precise and smoother driving in of the ground screws with a lower torque thanks to the pre-drilled hole.

3. Experience is an advantage

When it comes to the professional installation of ground screws, a certain level of experience is needed in order to drive in the screws with the necessary balance. Applying too much clamping pressure can destroy the drilled hole, and applying too little pressure can result in the screw driver “rotating empty”. In addition, it’s important to drive in the screws evenly, as with each rotation the ground screw must penetrate the ground in accordance with the thread pitch. Therefore, you need to make sure that you always keep an eye on the torque and the soil. If earth is moved upwards, it can significantly reduce the load-bearing capacity of the foundations as it may cause slipping and this may then mean that there is not sufficient surface friction between the pipe and soil. Any “burrowing” into the soil must therefore be avoided at all costs.

4. Keep an eye on the spirit level

Depending on the application, you have to work very precisely. This means that the installation tolerances must be kept extremely low. This is necessary as then the load bearing points of the structure can later be exactly adjusted to the foundations. In addition, you must always keep an eye on the spirit level in order to ensure a perpendicular driving in. Tilting and too high installation tolerances can lead to an incorrect and unfavourable loading of the ground screws, which may in turn cause other problems, such as the bending of the ground screws, for example. This can lead to a decrease in the load-bearing capacity of the foundations.

5. Torque documentation creates acceptance

You should document the torque during the installation of the individual ground screws, even if no evidence is required. These values can be compared with the results of the load-bearing test which – if they match – not only confirms the quality of the installation but also increases the acceptance of the solution by everyone involved in the project. In most cases, the documentation can only be done manually. But there are also some ground screw drivers which automatically document the torque with the help of a torque kit, for example the KRD 30 and KRL from KRINNER.

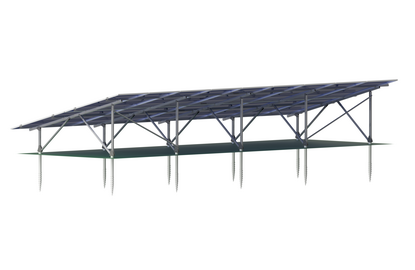

6. Use the right machine

Last but not least, it is of course important to choose the right ground screw driver to ensure a proper installation. Here, there are a variety of different designs available to choose from. It may be an electric manual ground screw driver, a hydraulic excavator add-on or a drill-guided installation device which is available both as a self-driving caterpillar and an excavator add-on. Each machine has its own application-oriented, specific advantages which means that they can cover a wide range of application possibilities. For example, if precision is important for your project, a drill-guided machine is recommended, but with narrow and small construction sites, a manual ground screw driver is entirely sufficient. All KRINNER ground screw drivers have been manufactured in-house. Therefore, Krinner is the only provider on the market that offers a complete system of products and installation technology to this extent.

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/1/7/csm_Bild_2003416679.jpg)

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/2/e/csm_MSG-Signet-Schwarz_ef33dcaf08.png)

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/4/5/csm_TERR_TM_V_CMYK_FC_Pos_5304b559c9.jpg)