Which machines can be used to drive in ground screws?

Which machines can be used to drive in ground screws?

Entry-level manual ground screw drivers

The original aid for manual installation is the screw driving tool or rod. They can be used to drive ground screws into the soil by hand without electric or hydraulic help. However, these tools are recommended for the installation of very small ground screw foundations in garden and hobby construction projects, such as when building a small sunshade holder, for example.

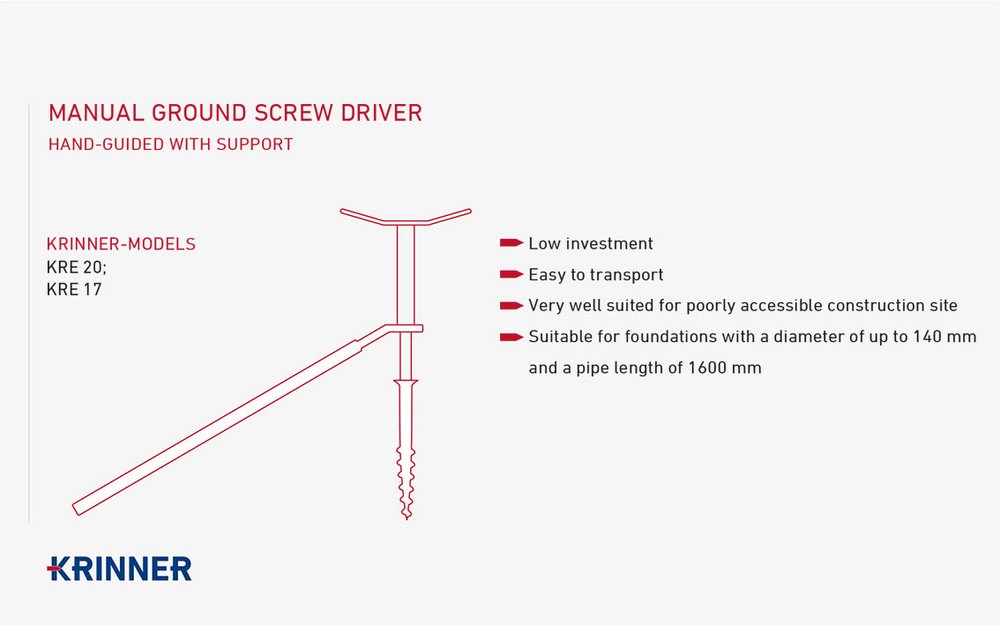

The electric manual ground screw driver should be thought of as an entry-level model for professional construction projects. It’s a comfortable option for installing ground screws at an affordable price. An electric manual ground screw driver consists of a drive unit, a handle and a telescopic rod for discharging the torque.

You can work effectively with this machine as it can be operated by one person and it makes it possible to easily install professional foundations, even on narrow and difficult to access construction sites. The device is relatively easy and light to transport and it even fits in the trunk of a car.

Manual ground screw drivers enable torques of up to 3,500 Nm and, depending on the soil composition, can be used to drive in ground screws with a diameter of up to 140 mm and a pipe length of 1600 mm. Despite the electrical drive, some manual force is still required. With the KRE 17 and the KRE 20, KRINNER Schraubfundamente GmbH offers two different variations of this type of machine.

Add-ons for caterpillars

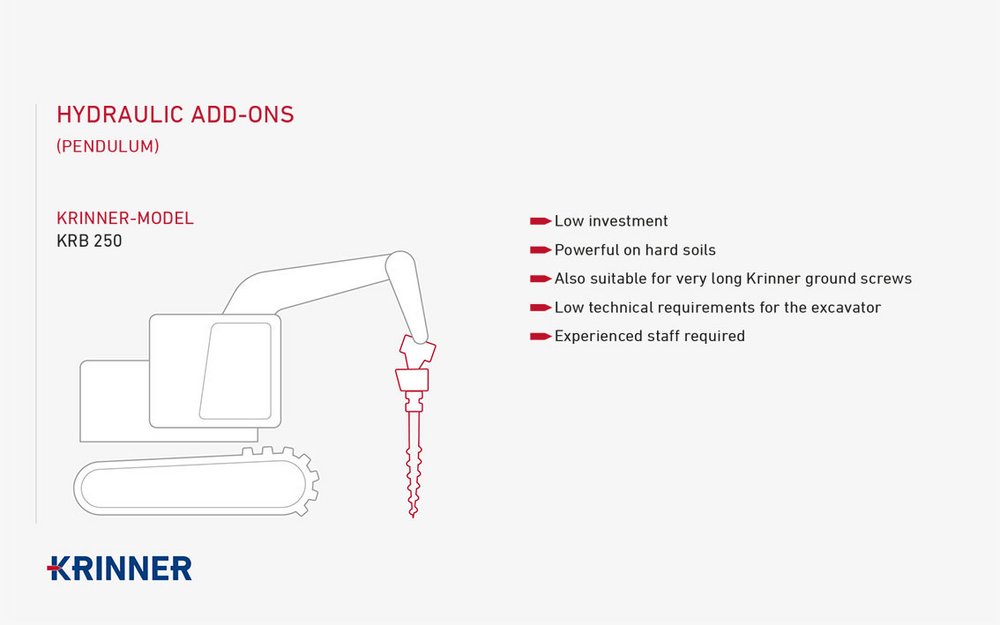

For firms that already have a caterpillar in their fleet, optimal machine utilisation can be achieved with hydraulic add-ons that can be used for driving in ground screws. This can either be a free pendulum or a so-called drill attachment. The free pendulum can be acquired for a fairly low price, it can be used to drive in long ground screws and can cope with torques of up to 20,000 Nm.

The pendulum also offers further advantages thanks to the carriage on the hydraulic driver which automatically orients in the correct direction and supports a perpendicular driving in. In addition, you can use the same unit to carry out any pre-drilling work. Free pendulums are particularly suitable for use with very hard ground, or even grounds with a rocky substrate or on building sites on sloping ground which can only be reached with the aid of an excavator arm. With the KRB 250, KRINNER now has one variant in the range.

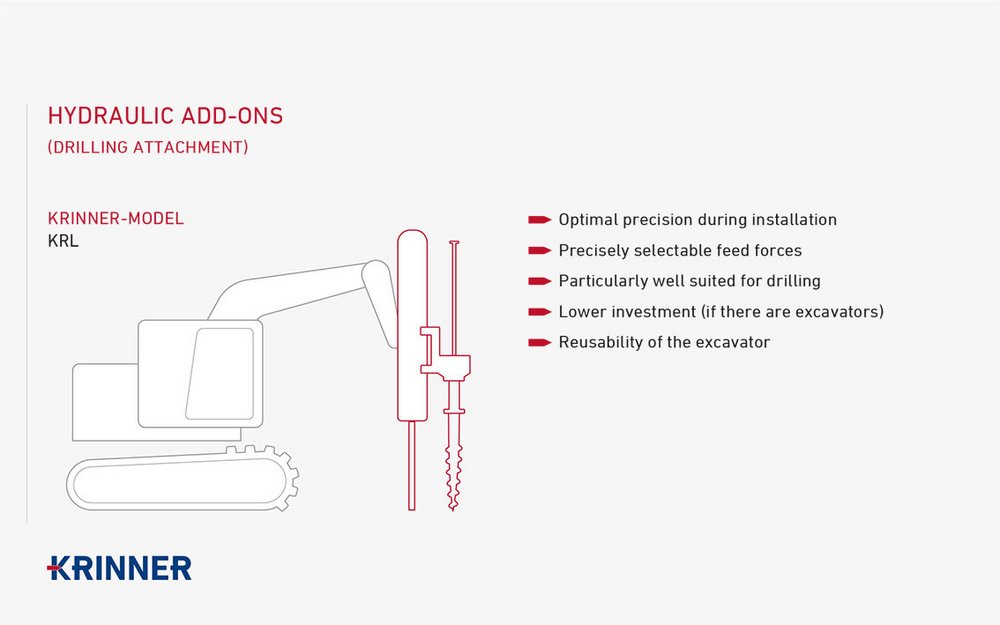

In principle, the drilling attachment offers the same advantages as the free pendulum but it is slightly more precise. The drilling attachment guide ensures a very precise and perpendicular driving with low installation tolerances. In addition, the feed force can be exactly controlled and any pre-drilling can be done precisely. With the KRL, KRINNER can offer customers this type of machine with a torque of 15,000 Nm.

Self-driving ground screw drivers

Drilling attachment-guided ground screw drivers are also available in the form of self-driving caterpillars. Not only are they useful in terms of installation thanks to their attachment-precision, but also due to their manoeuvrability and light weight. Because of this, they can easily reach narrow construction sites that larger caterpillars cannot without significantly damaging the ground.

Here the relatively low weight of just one ton means that they can be easily transported with a standard trailer. The KRINNER KRD 30 is clear example of this type of machine. It has a torque of 8,000 Nm and can be driven over surfaces with a gradient of up to 15°.

KRINNER as a leading provider

While the machines are all very different, there are some features that they all have in common. On the one hand, there is a wide range of accessories for screw-in tools and screw drivers which are needed for the various different ground screw series, and on the other hand the machines sometimes need different levels of experience and skill to be operated. As when it comes to the correct installation of ground screws, not only do you need the right machine but you also need the right installation expertise.

Another common feature: you can acquire all these machines from KRINNER Schraubfundamente GmbH. KRINNER is a leading provider of ground screws and is one of the only ground screw manufacturers on the market that also manufactures their own ground screw drivers.